Powering Predictive Maintenance: How Big Data Fuels AI Efficiency

Introduction: Have you ever wondered how industries predict equipment failures before they happen? According to McKinsey, predictive maintenance can reduce maintenance costs by 20% and unplanned outages by 50%. The secret behind this efficiency lies in the synergy between Big Data and Artificial Intelligence (AI). Big Data provides the vast amounts of information needed, while AI processes and analyzes this data to predict maintenance needs accurately. This article explores how Big Data enables AI in predictive maintenance, enhancing operational efficiency and reducing costs. By the end, you'll understand the critical role of Big Data in predictive maintenance and how AI leverages this data to revolutionize industry practices.

Body:

Section 1: Background and Context

Predictive maintenance is the practice of using data analysis tools to predict when equipment failure might occur so that maintenance can be performed just in time to prevent it. This approach contrasts with reactive maintenance (repairing equipment after it fails) and preventive maintenance (regularly scheduled maintenance regardless of condition).

The Importance of Predictive Maintenance

Predictive maintenance is crucial for industries like manufacturing, energy, and transportation, where equipment downtime can lead to significant financial losses and operational delays. According to a report by Deloitte, predictive maintenance can save industries billions of dollars annually by reducing downtime and extending the lifespan of equipment.

Section 2: Highlight Key Points

The Role of Big Data in Predictive Maintenance

Big Data refers to the vast volumes of data generated from various sources, including sensors, machines, and other industrial equipment. This data is essential for predictive maintenance as it provides the raw information needed to identify patterns and predict failures.

- Data Collection: Sensors and IoT devices collect real-time data on equipment performance, including temperature, vibration, pressure, and usage patterns.

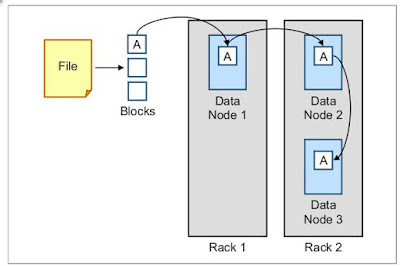

- Data Storage: Advanced storage solutions like cloud computing handle the massive amounts of data generated, ensuring it is accessible for analysis.

- Data Processing: Big Data technologies process and organize the collected data, making it ready for AI analysis.

How AI Leverages Big Data for Predictive Maintenance

Artificial Intelligence uses machine learning algorithms to analyze the processed data and identify patterns that indicate potential equipment failures.

- Pattern Recognition: AI algorithms analyze historical and real-time data to recognize patterns and anomalies that precede equipment failures.

- Predictive Models: Machine learning models predict future equipment behavior based on identified patterns, allowing for proactive maintenance.

- Continuous Learning: AI systems continuously learn from new data, improving their predictive accuracy over time.

Section 3: Practical Tips, Steps, and Examples

Implementing Predictive Maintenance Using Big Data and AI

- Identify Key Data Sources: Determine which equipment and sensors will provide the most relevant data for predictive maintenance.

- Invest in Data Infrastructure: Ensure you have the necessary data storage and processing capabilities, such as cloud services and data management platforms.

- Develop AI Models: Collaborate with AI experts to develop and train machine learning models tailored to your specific equipment and maintenance needs.

- Integrate with Maintenance Systems: Implement predictive maintenance insights into your existing maintenance workflows and systems.

Real-World Applications and Case Studies

- General Electric (GE): GE uses Big Data and AI to monitor and predict the maintenance needs of its jet engines and turbines, reducing downtime and maintenance costs.

- Siemens: Siemens' predictive maintenance solutions leverage AI to analyze data from industrial equipment, enabling timely maintenance and preventing costly failures.

Quotes and Studies

A study by PwC found that predictive maintenance can increase equipment lifespan by up to 25%. Additionally, IBM reports that companies using predictive maintenance experience a 10-20% reduction in maintenance costs.

Conclusion: Big Data and AI are revolutionizing predictive maintenance, offering industries a powerful tool to enhance operational efficiency and reduce costs. By collecting and analyzing vast amounts of data, AI can accurately predict equipment failures and schedule maintenance proactively. This not only prevents costly downtime but also extends the lifespan of critical machinery. As technology continues to advance, the integration of Big Data and AI in predictive maintenance will become even more sophisticated, driving further improvements in industrial efficiency. Embrace the power of Big Data and AI to transform your maintenance practices and stay ahead in the competitive landscape.

Comments

Post a Comment