Big Data-Driven Predictive Maintenance: Preventing Equipment Failures with Machine Learning

Introduction

How can industries like manufacturing and energy prevent costly equipment failures and downtime? The answer lies in Big Data-driven predictive maintenance using machine learning. According to a report by McKinsey, predictive maintenance can reduce maintenance costs by 25% and eliminate breakdowns by up to 70%. This approach leverages machine learning algorithms to analyze vast amounts of data and predict potential equipment failures before they happen. This article explores the significance of Big Data-driven predictive maintenance, highlighting its applications, benefits, and practical implementation strategies.

Section 1: Background and Context

Understanding Predictive Maintenance

Predictive maintenance involves monitoring equipment performance and using data analytics to predict when maintenance should be performed. Unlike reactive maintenance, which addresses issues after they occur, predictive maintenance aims to prevent failures before they happen. This proactive approach minimizes downtime and reduces maintenance costs.

The Role of Big Data

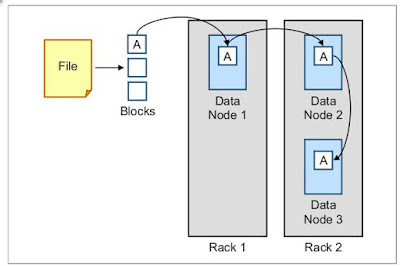

Big Data plays a crucial role in predictive maintenance by providing the necessary information for machine learning algorithms to analyze. Data from sensors, historical maintenance records, and operational logs are used to identify patterns and predict potential failures. The integration of Big Data with machine learning enables more accurate and timely predictions.

Section 2: Highlighting Key Points

Machine Learning Algorithms for Predictive Maintenance

Several machine learning algorithms are used for predictive maintenance, including:

- Regression Analysis: Predicts the likelihood of equipment failure based on historical data.

- Classification Algorithms: Categorizes equipment conditions to determine the need for maintenance.

- Clustering Techniques: Identifies patterns and groups similar data points to assess equipment health.

- Neural Networks: Processes complex data to make accurate predictions about equipment performance.

Benefits of Predictive Maintenance

Predictive maintenance offers numerous benefits for industries:

- Reduced Downtime: Prevents unexpected equipment failures, minimizing production disruptions.

- Lower Maintenance Costs: Optimizes maintenance schedules, reducing unnecessary repairs and associated costs.

- Improved Equipment Lifespan: Ensures timely maintenance, extending the lifespan of equipment.

- Enhanced Safety: Identifies potential hazards before they cause accidents, improving workplace safety.

Applications in Manufacturing and Energy

Predictive maintenance is widely used in manufacturing and energy sectors. In manufacturing, it helps maintain machinery and production lines, ensuring continuous operations. In the energy sector, predictive maintenance monitors equipment like turbines and transformers, optimizing their performance and preventing failures.

Section 3: Practical Tips and Examples

Practical Tips for Implementing Predictive Maintenance

- Deploy Sensors: Install sensors on critical equipment to collect real-time performance data.

- Choose the Right Algorithms: Select machine learning algorithms that are suited to your specific equipment and industry.

- Integrate with Big Data Infrastructure: Ensure seamless integration with your Big Data infrastructure to process large datasets efficiently.

- Train Your Model: Use diverse and comprehensive datasets to train your machine learning models for accurate predictions.

Example Case Study: General Electric (GE)

General Electric (GE) employs predictive maintenance to optimize the performance of its industrial equipment. By analyzing data from sensors and historical maintenance records, GE's machine learning algorithms predict potential failures and recommend timely maintenance. This approach has significantly reduced downtime and maintenance costs, improving overall operational efficiency.

Conclusion

In conclusion, Big Data-driven predictive maintenance using machine learning offers transformative benefits for industries like manufacturing and energy. By leveraging vast amounts of data and advanced algorithms, businesses can prevent equipment failures, reduce downtime, lower maintenance costs, and enhance safety. As technology continues to evolve, adopting predictive maintenance will be crucial for maintaining a competitive edge and achieving long-term success. Implement these strategies to unlock the full potential of predictive maintenance and drive innovation in your organization.

Comments

Post a Comment